To reach our climate goals, we need to start making big progress in these three key industries.

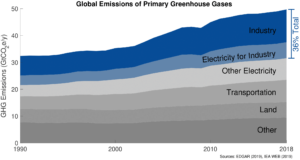

Industrial production is responsible for one-third of global greenhouse gas emissions. These emissions mostly come from production of a small number of very emissions-intensive materials like steel, cement, and basic chemicals. In order to reach our climate goals, we need to start making big progress in these industries.

Industrial production is responsible for one-third of global greenhouse gas emissions. These emissions mostly come from production of a small number of very emissions-intensive materials like steel, cement, and basic chemicals. In order to reach our climate goals, we need to start making big progress in these industries.

Unfortunately, low greenhouse gas alternatives to these basic materials are not widely available. There are lots of reasons for this, but mostly they boil down to no incentives to produce clean materials. The best way to create those incentives is to create a market so producers of low-emissions materials can be paid a premium price.

There are four reasons why creating markets for such materials will be effective:

- We need to justify major additional expenditure. All of the ways to make meaningful reductions in emissions will require capital improvements to existing factories, new factories, increases in operating costs, or a combination of these. Industrial capital is expensive—even modest upgrades can cost tens of millions of dollars. Manufacturers will want to be sure their investment in low-emissions process upgrades will yield higher revenues than business as usual. Market demand will justify new, cleaner production processes so firms can be sure there will be customers ready to buy their low-emissions materials.

- Dirty products won’t be able to undercut clean products. We could use regulation to require factories to invest in clean production, but steel, cement, and chemical products are traded all over the world. If we’re not careful, dirty materials produced outside the reach of the regulations could undercut the clean materials on price, and the manufacturers who invested in clean production would lose business. This problem goes away if we focus on building demand for the final products: the cars made with clean steel or the infrastructure made of clean concrete. The rule would be that in order to sell in this market, the materials need to comply with an emissions standard, no matter where they were made.

- The rules will be enforceable. Creating markets also lets you focus on the materials that have the biggest climate impact and that don’t create huge compliance problems. Instead of having to figure out the supply-chain emissions of every single product that is being sold in the economy, regulators will just have to verify the documented supply-chain emissions of the specific products that are seeking access to the market.

- The final consumers will hardly notice the costs. The cost of raw materials like steel, cement, and basic chemicals make up a very small portion of the cost of finished goods. For instance, structural materials like steel and cement are typically only a few percent of the price of a building. Even in a very steel-intensive product like a car, the steel is only about 3% of the price. The ethylene in the plastic is much less than 1% of the price of a bottle of water. Most of the cost of these products is in the labor of transforming materials into finished goods. So even early-on, when potentially higher-cost, low-emissions production processes are coming online, there will be almost no impact on the cost of the final products. By creating market demand for products made of low-emissions materials, we ensure that the costs of reducing emissions are paid by the final consumers, who can most easily afford it.

There are lots of ways to create a market, and different ones will be appropriate in different contexts. For example, we could:

- Require that all building materials that go into roads and other public construction projects must be low-emissions.

- Create voluntary certifications that allow consumers to choose low-emissions products.

- Regulate the supply-chain emissions of specific products, like cars or appliances.

- Enact subsidies to make up the difference in price between low-emissions and high-emissions materials.

- Use codes, standards, and specifications that have preferences for low-emissions materials.

The right option will depend on the particular product and the particular circumstances, but we need to get started now. All of the other things we need for a climate-safe industrial sector—technology development, financing and investment, massive retooling—won’t happen unless we create places and structures where manufacturers can profit by selling clean materials.

Civil society is already working to accelerate the transition to climate-safe industry and manufacturing. Grantees and allies of ClimateWorks are already working on many of the approaches listed above, and have already seen important progress. For example, education and outreach activities from groups like the Sierra Club and the BlueGreen Alliance was critical to passing California’s first-in-the-nation Buy Clean law, which requires certain building materials in public projects have lower greenhouse gas emissions. ResponsibleSteel is creating the first multi-stakeholder voluntary certification for responsibly-produced steel. We are now working to scale up these activities in partnership with our network of aligned foundations and NGOs.