In the last five years, batteries have gone from being associated with ubiquitous AAs used to charge small electronics, to a prominent emblem of the clean energy transition. With 8.5 million electric vehicles (EVs) on the road today, batteries are on the path to single-handedly power transportation electrification through zero-emission vehicles, replacing polluting gasoline and diesel engines. As the world inches toward 100% electric road transportation across modes, as highlighted in the global Drive Electric Campaign, battery technology continues to rapidly improve. A recent report by Union of Concerned Scientists highlights that battery density has increased threefold from 24kWh in the 2010 Nissan Leaf to 75kWh in Tesla’s 2020 Model 3, while in the same time span, the average price of battery packs decreased from $1,200 per kWh to $137 per kWh.

Why batteries matter and how they need to be improved

The total emissions associated with manufacturing and operating electric vehicles are dramatically lower than those of a gasoline counterpart. The emissions savings range from 35% in countries with coal-heavy power generation, to 55% in the U.S. and countries with similar a grid mix. In Europe, an average electric vehicle is already three times better in terms of emissions than an average diesel or gasoline car.

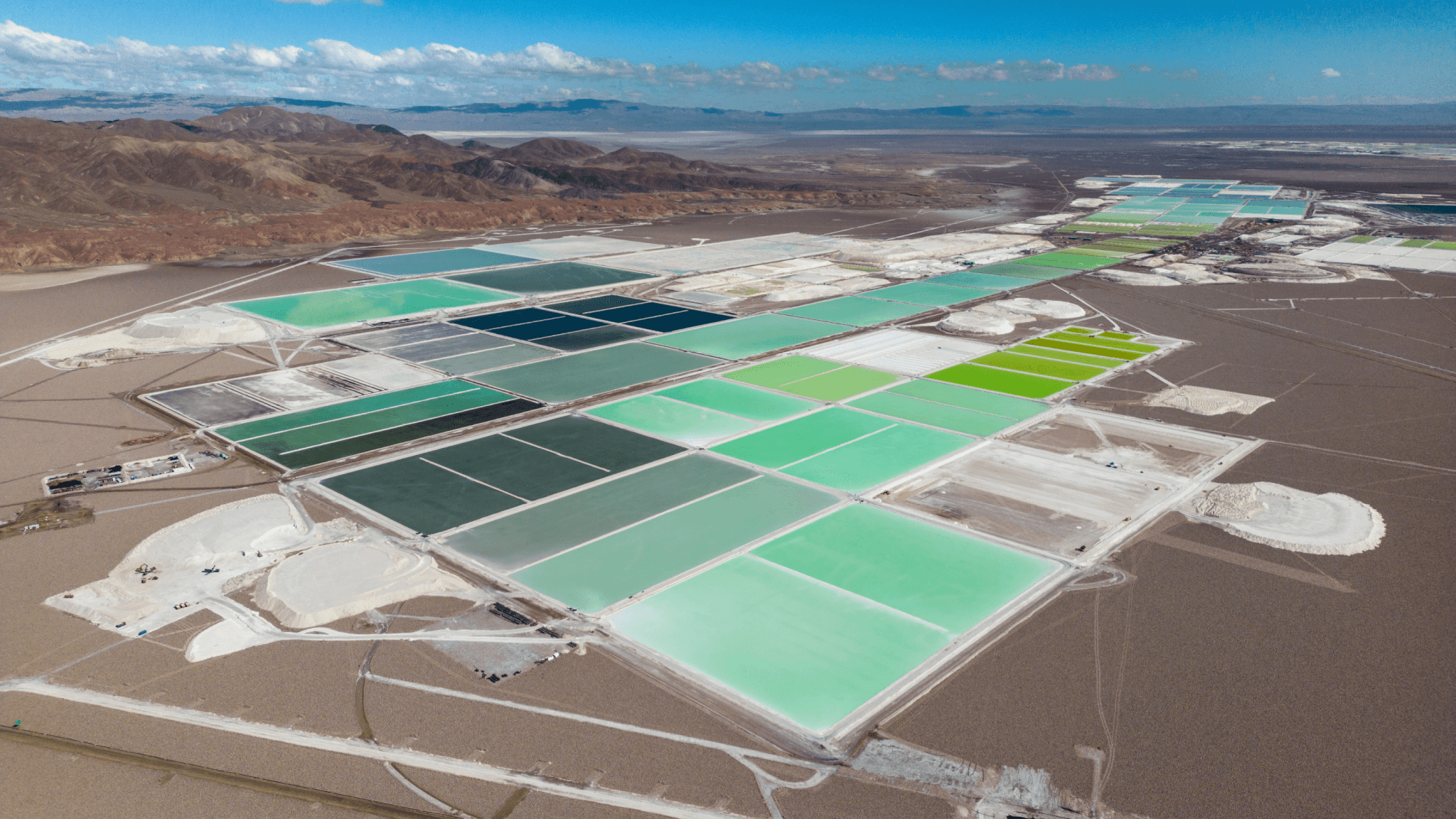

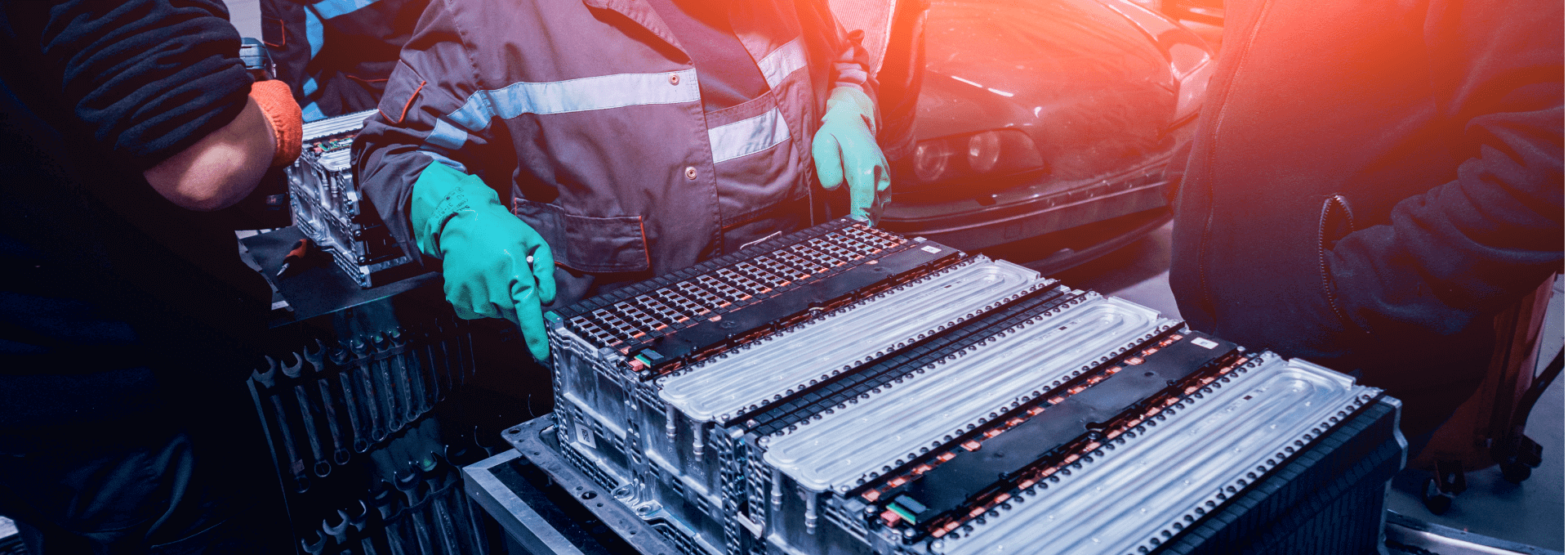

Battery manufacturing is the second-largest emissions hotspot in an electric vehicle’s lifetime emissions, but the impact will be reduced almost threefold in only a few years, due to better processes and scaled-up production. Where produced with clean high-renewables electricity, batteries are already low-carbon today. Beyond incentivizing low-carbon energy, ensuring battery materials such as cobalt, nickel, and lithium are recycled at the end of their life is essential. This already happens in China, and lawmakers in both California and Europe are putting in place ambitious circularity requirements. Finally, ethical sourcing of raw materials is the last key piece to the puzzle, ensuring that any metal that finds its way to an electric car (or any other vehicle) has been sourced responsibly, in line with the U.N.’s due diligence guidelines.

Policy and industry actions on EV batteries

As electric vehicle uptake is ramping up, key markets are starting to take action to lock in sustainability practices across EV battery supply chains and position themselves as the hubs for battery production. Last year, the European Commission introduced a first-of-its-kind draft law seeking to set a precedent for a sustainable EV battery supply chain by mandating ethical sourcing, minimum recycling thresholds, and emissions disclosure. China enacted detailed policy and guidelines for recycling EV batteries and promoting second life uses. And India launched a National Programme on Advanced Chemistry Cell Battery Storage, which outlines an opportunity and plan for India to indigenize the production of battery cells.

On the supply chain side, the industry is starting to pick up pace in advancing best mining practices that preserve human rights and the environment. Most recently, Ford followed BMW and Daimler as the third automaker to join the Initiative for Responsible Mining Assurance (IRMA), the strongest voluntary commitment to bring transparency and accountability to their supply chains. The Global Battery Alliance (GBA) has also been set up as an industry forum to drive a sustainable battery value chain. While it can do more to push for fair mining practices in large-scale mining, its Battery Passport project is a notable step in the right direction

Philanthropic opportunity for sustainable EV battery supply chains

Despite meaningful recent progress, there is more to be done to lock in sustainable EV battery supply chains, and philanthropy can help by supporting several areas of work.

- Policy and best practices: Philanthropy can help elevate policies introduced in the EU, China, and India, and support learnings exchange across battery-producing countries. Policy packages should include recycling, ethical sourcing, production capacity, emissions disclosure and regulation, and circular design standards.

- Industry and supply chain: Philanthropy can support advocacy for industry to join platforms such as IRMA to drive and normalize sustainable supply chains that preserve human and labor rights as well as environmentally sound practices. It can also boost the ambition of organizations such as the GBA, as well as support better enforcement of existing standards and initiatives (rather than looking to new standards in an already complex matrix of initiatives).

- Emissions research and communications: Philanthropy can support non-governmental actors and academia to continue measuring and communicating the constantly improving emissions track record of batteries. A lot of myths, notably by electrification opponents, are still out there, so positive and simple stories showcasing clean, circular battery value chains are helpful to educate the public and policymakers.

- Energy transition opportunities: Philanthropy can facilitate broader thinking about the opportunities related to shaping the trajectory of practices within clean energy supply chains that center people and environment. This includes rethinking standards to promote best-in-class batteries, waste designation for EV batteries enabling end-of-life practices, international environmental and labor standards for mining and material processing for batteries entering the market, design standards to optimize recyclability, and many others.

Transportation electrification is set to correct decades of harmful exhaust fumes from gasoline and diesel engines by eliminating tailpipe emissions, reducing air pollution, and curbing related impacts to the respiratory health of communities in transport-dense areas such as cities, shipping depots, ports, and others. With proactive action on EV battery supply chains, there is an opportunity to shape the benefits of the clean energy transition even further, by locking in sustainable practices that center people and preserve the environment from the moment a battery mineral is safely sourced from the ground to the moment it is efficiently recycled back into a new battery.